GRP Sectional Water Tank

- Home

- GRP Sectional Water Tank

GRP Sectional Water Tank

GENERAL SPECIFICATIONS

Standard :

Singapore Standard SS245: 1995 Cross reference to British Standard BS 7491 Part 3:1994 and BS EN 13280:2001

Materials :

Resin- Isophthalic unsaturated polyester resin conforming to BS 3532 specification

Fiber Glass- Low alkali fibre glass conforming to JIS R3411 to R3417 or BS 33396, BS 3496 and BS 3749 specifications

Manufacturing Process :

SMC hot pressed compression moulding

Tank Structural Support :

External:

– Standard Type : Hot Dipped Galvanised Steel

– Optional Type : External Braced type (Metal-Free tank internal for non- partitioned

tank only).

Internal:

– Standard Type : SS 304 Tie-Rod or Cleat Angle Stay

– Optional Type : SS 316 Tie-Rod pr Cleat Angle Stay

Roof Support – PVC Vertical Poles and GRP roof panel stiffener

Sealant :

Non toxic PVC foam

Bolt, Nuts, Washers :

External:

– Standard : Hot Dipped Galvanised Steel

– Optional : SS 304/A2 or SS 316/A4

Internal:

– Standard : SS 304/A2 (In-contact with water)

– Optional : SS 316/A4 (In-contact with water)

Roof – Hot Dipped Galvanised Steel or unless otherwise specified

Ladder :

External – Standard : Hot Dipped Galvanised Steel

Internal – Standard : PVC

– Optional : GRP or 316

Water Level Indicator :

Standard Reversed Reading Mechanical Ball Float Type with Mouse

Optional : Direct Reading Clear Tube Type

Nozzle Panel :

Flat panels will be provided for any type of piping materials.

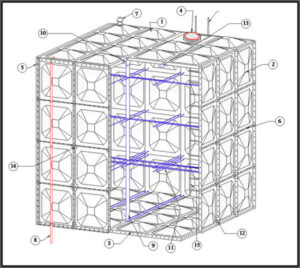

BLOW OUT VIEW OF GRP TANK

|

Main Component

|

External Structural Support

|

Internal Structural Support

|

Tank Accessories

|

|

Top panel (1) |

Body angle (6) |

Pole (9) |

Access manhole (4) |

|

Side panel (2) |

Corner angle (5) |

Pole support (10) |

Air vent (7) |

|

Bottom panel (3) |

Tie-rod bracket (12) |

Tie-rod (11) |

Water level indicator (8) |

|

Side panel support (14) |

Roof support (13) |

Internal ladder (15) |

|

|

External ladder (1) |

General Specifications

STANDARD

Pressed steel sectional water tank constructed with hydraulically pressed flanged panels, conform to

BS1564:1975andSS22:1979

MATERIALS FLANGES OF PLATES

The steel used in the manufacture of the tank plates, stays and cleats conform to the requirement of BS4360:1972 grade 43A or ISO equivalent

Tank panels pressed with a combined double flange at an

angle of 45 degree and 90 degree to the face of the plate in four sides

FINISH

Hot Dip Galvanised conform to ISO1461

STANDARD THICKNESS

FOR 1.22 mX 1.22 m TANK PANEL

| Type | 1.22 m (H) | 2.44 m (H) | 3.66 m (H) | 4.888 m (H) |

|---|---|---|---|---|

| Tank covers | 1.5 mm | 1.5 mm | 1.5 mm | 1.5 mm |

| 4th side panels | 5.0 mm | |||

| 3rd side panels | 5.0 mm | 5.0 mm | ||

| 2nd side panels | 5.0 mm | 5.0 mm | 5.0 mm | |

| 1st side panels | 5.0 mm | 5.0 mm | 5.0 mm | 5.0 mm |

| Bottom panels | 5.0 mm | 5.0 mm | 5.0 mm | 6.0 mm |

Note: Specification may vary according to client’s requirement.

STANDARD

Pressed stainless steel sectional

water tank constructed with hydraulically pressed

flanged panels

MATERIALS

The tank panel, tie rods, stays and cleats are made

from Stainless Steel

Grade 304/316

JOINTING MATERIALS

Non toxic PVC

foam to be used for all jointing between tank panel flange

STANDARD THICKNESS

FOR 1.22 m X 1.22 m TANK PANEL

| Type | 1.22 m (H) | 2.44 m (H) | 3.66 m (H) | 4.88 m (H) |

|---|---|---|---|---|

| Tank covers | 1.5 mm | 1.5 mm | 1.5 mm | 1.5 mm |

| 4th side panels | 2.5 mm | |||

| 3rd side panels | 2.5 mm | 2.5 mm | ||

| 2nd side panels | 2.5 mm | 3.0 mm | 3.0 mm | |

| 1st side panels | 2.5 mm | 2.5 mm | 4.0 mm | 4.0 mm |

| Bottom panels | 2.5 mm | 2.5 mm | 4.0 mm | 4.0 mm |

*Optional items are to be quoted separately upon request.